Stay informed with our latest news and offers.

By subscribing, you accept our Privacy Policy.

Published on: 08 August 2025

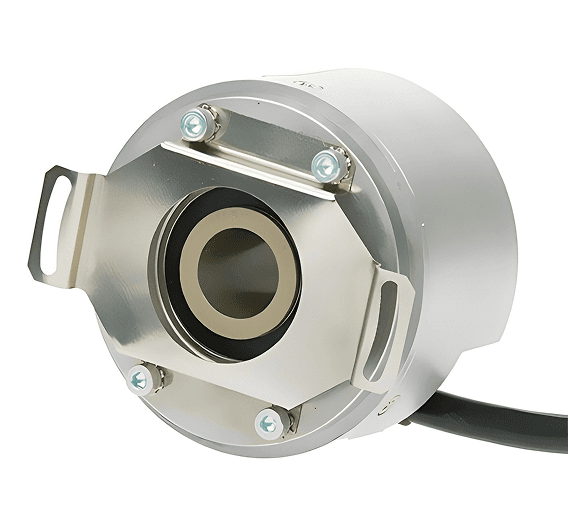

For rotary encoders, resolution means how many distinct steps (pulses or bits) the encoder outputs per full shaft revolution — commonly expressed as PPR (pulses per revolution) for incremental encoders or bits (positions per revolution) for absolute encoders.

High enough resolution is critical: too low and the controller won’t get precise feedback; too high, and you might exceed the encoder’s design limits causing signal errors.

Define the minimum angular increment your application needs – call that θ (in degrees).

Example: You need to detect every 3°.

Compute the number of points per revolution needed:

For θ = 3°, N = 120 pulses per revolution.

Check feasibility against encoder hardware limits:

Exceeding this causes degraded output, missed pulses, or cumulative error.

Quadrature decoding (optional):

If using A/B channels with quadrature and counting both rising and falling edges, you can effectively get 2× (X2) or 4× (X4) the nominal pulses, increasing effective resolution.

Absolute Encoders (Bit-based)

First find how many discrete positions you need per 360°, using the same angular increment logic:

Then pick the smallest bit-depth whose number of unique codes ≥ N. For example, a 14-bit encoder gives 2¹⁴ = 16,384 positions per revolution — enough for applications needing fine angular resolution.

Automation

From cables to switches — explore how industrial ethernet products improve automation efficiency. Ideal for OEMs and machine builders.

Automation

Explore the advantages of modular connectors like Han-Modular® for flexible power, signal, and data transmission in compact industrial systems.

OEM

Learn how SR Indus partners with leading brands to offer reliable automation solutions for OEMs and machine builders across India.